Are your business process workflows defined for effective work management?

If you want to have an effective work management process you must create detailed workflows for every aspect of the process. If you haven’t sat down as a group and discussed who does what task for work management you are going to have a problem. We’ve seen some common mistakes that plants make when they are creating their work management workflows.

- Instead of focusing on what people need to do to complete a task, they focus on the CMMS instructions.

- The workflow is too detailed or too high level

- The activity doesn’t include who is responsible and accountable for doing the task

- The person’s work management job description doesn’t agree or match the workflow

Detailed workflows creates improved cooperation and cohesion

Think about it, when you have designed a workflow that has definitive tasks and who is responsible and accountable for making sure that task is completed, you can easily create a job description for both of those roles in the organization. By clearly defining each task and assigning a role to that task you will eliminate the “That’s not my job” or the “Who’s supposed to do this task?” comments and questions at my plant. You will immediately improve cohesion and cooperation when people know whats’ expected of them.

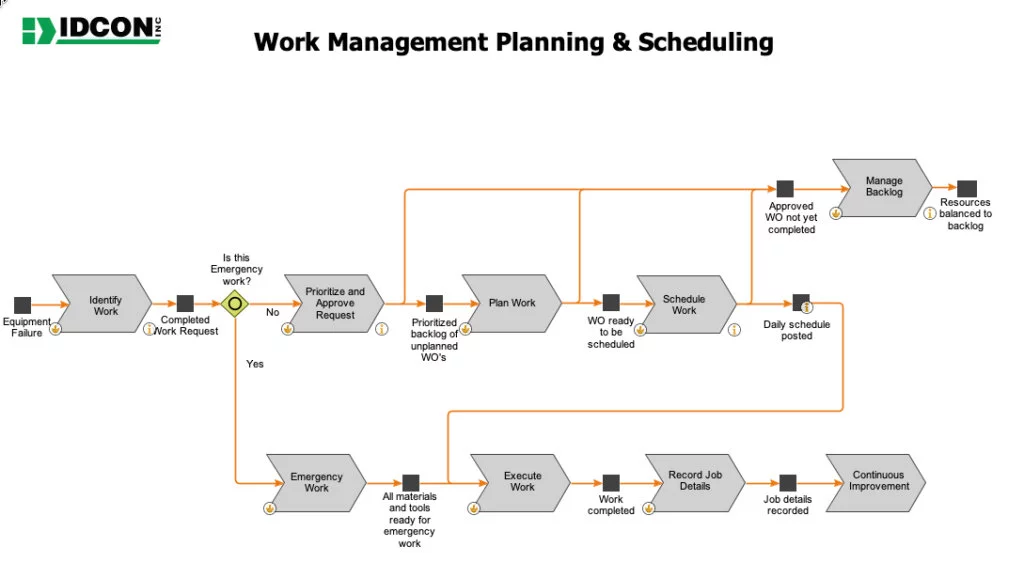

Notice each of the process in the workflow has an input and output. Additionally, this one contains a question, “Is this emergency work?” which bypasses the Prioritize and Approve, Plan Work and Schedule work processes. Emergency work has to be defined so that it’s not used as a crutch for emotional priorities. You can download our priorities guideline to help your plant have a better grasp of emergency work.

In the workflow above, in addition to identifying each person responsible and accountable, you’ll see the cut off times for when key activities like meeting and tasks are to be completed. Because you include these details you will remove any confusion about when a task needs to be completed and who is responsible or accountable for a task.

Now that you have tasks identified with a role who is responsible for them, now you can easily create a job description with details of what this role does for this particular process. So the heading of the section in their job description could be “Maintenance Scheduling” with each of the tasks clearly defined within the section. Again, this will improve understanding and clarify who does what.

You also see where other processes that affect the main process fit in. You see that Kitting Parts, a Materials and Spare Parts process, is integral to being able to execute work. That workflow then identifies who is responsible for kitting parts, where those parts will be delivered, and when. This is going to improve how work is executed because the maintenance team will know who to contact if parts are not staged in the area. Again, clear workflows will improve cooperation and I believe even the morale at your plant.

I challenge you to take a look at your current business process workflows and see if they:

- Have the right amount of detail

- Identify who is responsible, accountable, consulted and informed (RACI)

- Identify all processes that impact the overall process

- Show the input, output, meetings and timing of key tasks

- Match the current job descriptions

If you need help to improve your reliability and maintenance management business process workflows, contact us. We’ll sit down with your team to develop the most effective workflows for your organization.