What is a plant Shutdown and Turnaround?

A plant “turnaround” is defined as a major plant maintenance shutdown, typically involving the entire plant or multiple areas and lasts for several days (or if not properly planned and scheduled can last longer than expected). Some organizations have both Major (more than 24 hours) and minor (24 hours or less). In many cases, minor shutdowns can have a bigger impact on lost production.

When we’ve been at client sites, we often hear that Shutdown/Turnarounds aren’t managed well. Late start-ups make it impossible to complete work on time. Different departments having disparate objectives makes it impossible to work as a team.

And most egregious, not having a set Shutdown/Turnaround process and schedule causes confusion and inefficiency throughout the plant, mill, or mine.

6 Phases of Shutdown and Turnaround Management

At IDCON, we divide plant Shutdown and Turnaround management into 6 phases. The goal of the six phases is to drive unscheduled downtime to zero as well as increasing Overall Production Efficiency (OPE) to create the opportunity to increase output. Creating a process with common goals is vital to achieving world-class reliability and maintenance.

This post will detail the four of the six phases. To learn more about all the Phases, you can either buy our Shutdown Turnaround Optimization Process Practical Guide or join us for our next training course. You can also watch our Shutdown/Turnaround playlist on YouTube.

Phase 1: Strategic

What is the purpose of the Strategic Phase?

The Strategic Phase of Shutdown/Turnaround Optimization Process (S-TOP) focuses on the frequency/interval and duration of the shutdown, organization and management of the shutdown, the use of contractors, long-term strategy for shutdown, and a strategy for the current shutdown. At the end of the Strategic Phase (if the steps are followed), you will have increased run time, decreased frequency of shutdowns, optimized outage duration, and good coordination with the overall business plan.

Common mistakes in the strategic phase of shutdown and turnaround management

Failing to identify requirements and shutdown drivers

- Not planning for or meeting market or seasonal demand

- Equipment deterioration and maintenance demands, i.e., Major Maintenance

- Process and operational demands unmet

- Not meeting regulatory requirements

- Capital project opportunities not identified

Your organization must identify the business requirements and drivers. If there is no plan on how to meet market and seasonal demands on the products, production won’t be able to meet demand and it will interrupt the high season and customers’ deliveries won’t be made.

If major maintenance items that need a shutdown aren’t done, such as boiler inspections and pressure valve testing, production losses will occur due to break-in and emergency work to fix problems. Failing to strategize Shutdown/Turnarounds properly can also cause missed capital project opportunities.

Failing to identify roles and responsibilities for Shutdown/Turnaround

A successful Shutdown/Turnaround organization requires identifying roles and their responsibilities. Organizations should have:

- A Turnaround Manager/coordinator to coordinate between different departments.

- A steering committee to set objectives, policies, monitor Key Performance Indicators (KPIs), and control the budget.

- Coordinator(s) for contractors

If the turnaround is large enough, there will be many outside contractors involved and if there is a lack of organization, it is impossible for them to be efficient and beneficial to your organization.

When contracting work, identify which work will be outsourced, consolidate the number of contractors, identify contractor coordination, decide on the selection criteria for contractors and verify qualifications, and evaluate the contract work at the end of the project. There must be quality control in terms of contractor work just like work done by team members in the plant, mill or mine or else hiring them will be a waste of time, capital, and resources.

Failing to schedule properly for the Shutdown and Turnaround

- Lack of a detailed schedule showing all activities, deadlines, and responsibilities to prepare for the turnaround

- No 3-5-year schedule is in place

- The shutdown cycle and approximate downtime needed are not determined

This example is from IDCON’s Maintenance Planning and Scheduling Book.

If the organization doesn’t develop a 3-5-year long term schedule, the Shutdown/Turnaround process will continue to be inefficient and cause greater cost, lost time and production losses each time it is done. Creating the schedule properly allows the organization to determine approximate downtime based on business requirements that have been decided upon.

Developing a countdown schedule is crucial because it gives the whole organization a direction on what to prepare and when. This should be detailed with activities, deadlines, responsibilities, how to prepare for the turnaround, and anything else needed to get the job done well and on time.

It can also be a vehicle for holding people accountable.

Phase 2: Work list

The purpose of the Work list Phase (or scope review) in the Shutdown -Turnaround Optimization Process (S-TOP) is to make sure that the correct work is selected.

In this phase, your organization identifies the work that is critical to support production reliability.

- decide if work needs to be done at the next shutdown, deferred to another time, or moved to on the run

- reduce the shutdown work scope

- decide on tasks that should be done before or after the shutdown

- identify items that have long lead times

- identify and eliminate non-value adding jobs

- prioritize work accurately through selecting work based on risk

- review Fixed Time Maintenance (FTM) work.

This phase is critical to the determining the time required for the plant production to be offline.

Common Mistakes in the Work list Phase

There are no formal meetings scheduled to review the work scope

In general, a worklist development team is led by the Operations Manager and the Maintenance Manager (there can be more), but all too often they may not take responsibility for setting up and attending meetings. Read more about Operations’ role in shutdown scheduling here.

Those responsible for the meeting should prepare and distribute an agenda and have a process to clean and prepare the worklist before the meeting starts. It wastes time if this must be done during the meeting.

These meetings should be included in the countdown schedule so that the date and time is designated for when a decision needs to be made about what to include in the shutdown. The work list determines the total shutdown scope. There needs to be a process in place to screen and evaluate risk or else work that doesn’t need to be included in the shutdown may be added, wasting time.

There is no process to screen and evaluate risk

If the scope of work is not understood, it is very difficult to develop a budget and control the cost of the shutdown. Make sure only work that sustains or increases production is identified as part of the work to be done in the shutdown. To determine this, ask the questions below about each job using Risk Based Work Selection:

Below are some examples of work that have been on work list review. See how well you do at answering the questions using the RBWS method.

Shutdown and Turnaround Work List Examples

Work Order #1: 600-megawatt combined cycle power plant steam turbine

The risk of not doing the work is too high based on the history of breakdowns of the steam turbine; it cannot be deferred to the next shutdown; the work can be executed economically and safely outside the outage (the spare pump is in place; approved ship is in place within region with two weeks turnaround); the work scope cannot be reduced; the work item does not remain in the outage scope.

The pump should be repaired and put back in service without shutting down the entire steam turbine.

Work Order #2: 600-megawatt combined cycle power plant steam turbine (same plant)

In this case, the feedwater pump recirculation valve is pulsating, vibrating, and making a loud noise. This is a high priority.

According to the Risk Based Work Selection process, the risk of not doing the work is too high so it must be done – there is no history available on the failure. It cannot be deferred to the next shutdown. The work cannot be done economically and safely outside the outage because the recirculation valve is connected to both feedwater pump and cannot be isolated. The unit must be shut down to work on the control valve and there may also be a problem with the check valve.

The work scope cannot be reduced.

So, as you can see, the Work list Review Phase can improve the duration of your shutdown/turnarounds by ensuring the work is valid for the next shutdown. When was the last time you reviewed the work being done during your shutdown/turnarounds? I challenge you to review those “standard shutdown jobs” and see if they really must be done during a shutdown.

Phase 3: Planning

What is the purpose of the Planning Phase in Shutdown/Turnarounds?

The purpose of the Planning Phase in Shutdown/Turnaround Optimization is to plan the jobs from the worklist created in Phase 2, the start-up and shutdown activities, and the safety and environmental procedures. To read more about work safety, read this short series Part 1 and Part 2.

If executed correctly, the Planning Phase will result in downtime reduction, mitigation plans, the most critical jobs being planned first, and contracted jobs being planned.

Tradespeople will be able to complete work efficiently, knowledgably, and on time; downtime and shutdown duration will be optimized; and coordinated use of resources will be optimized.

What activities are done during the planning phase?

Pre-Shutdown Inspections

Pre-shutdown inspections provide us with valuable information before the shutdown. These inspections reveal corrective work or pre-fabrication that needs to be done before shutting down, where shops and pre-fabrication areas need to be set up, if part specifications are correct, if cranes or rigging devices are needed, if scaffolding is needed, any equipment modifications, quality control procedures before and after the job, which crafts are needed where, physical conditions and environmental protections needed, etc.

Having this information ensures that the right work is being done during the shutdown and that the problem needing solving is understood.

It is good practice to use a template when planning jobs, whether it is daily, weekly or shutdown work. It is easy to get stressed about making mistakes and become disorganized. Having a checklist while scoping out the job ensures that nothing will be missed and that the job description will be thorough. If you don’t have a template, you can get one as part of our Maintenance Planning and Scheduling training, both our instructor led and self-paced courses give this resource to our students.

Scoping out the Job

There are specific items included in the planning checklist template for scoping out the job. The first is a clear and thorough job description including job steps so that crafts can perform the work safely and efficiently. There needs to be communication in terms of the production interface. This can help avoid delays such as forgetting to lock out a piece of equipment in time or missed opportunities for operations and maintenance to work together on the job.

Job scope also includes cost estimates, parts needed for the work, kitting, any necessary PPE identified, utilities needed (air, water, electricity), chemicals and safety data sheets needed to regulate use of the chemicals, and any equipment and tools needed. An important part of this process is feedback sessions about the work to gather information for next time if it is a repetitive job (as many are).

Review Shutdown/Turnaround Optimization Plans

After planning, especially for a major outage and turnaround, it is best practice for the maintenance manager or department manager to review all job plans, specifically if they involve the critical path, and to give feedback to the planner. Having an extra set of eyes (management) provide feedback on job plans, making sure nothing is left out, and then approving the plans can only help with the quality of the shutdown plan.

Phase 4: Scheduling

What is the purpose of the Scheduling Phase?

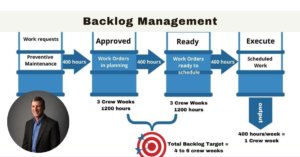

The focus during the Scheduling Phase is on integrating schedules, the critical path, shutdown execution management, logistics, and organizing resources (including contract management). Executing the Scheduling Phase correctly will result in shutdown preparedness, efficient and high-quality work, better communication, developed contingency plans, and resource leveling and scheduling.

Common Mistakes in the Scheduling

- Shutdown schedules are not integrated across the organization.

- Work is added into the schedule too late.

In many plants, mills, and mines, the shutdown schedules are not integrated between different functions such as engineering, maintenance, and operations, and that work is often added to the schedule too late, causing delays and interruptions to work already scheduled.

Integrating Plant Shutdown Schedule

What is scheduling exactly? Maintenance scheduling covers “who” is doing the work and “when” they will do the work, and coordinates with materials, equipment, and other departments and functions involved in the job.

To have a successful shutdown, all activities need to be integrated and coordinated into one master schedule to avoid any delays, inefficiency, and unsafe situations. This is usually done by the Shutdown Manager. Another important part of a successful shutdown is shutdown schedule compliance. Watch my video, You’re doing it wrong! Shutdown schedule compliance to learn more.

It is a common mistake for different departments working on the same equipment at the same time because they are not operating under an integrated schedule. For example, on a paper machine during a Capex project, I saw engineers upgrading the headbox at the same time as maintenance was changing the breast roll. Both tasks were delayed because they can’t be completed on the same machine at the same time. In the end, the startup was delayed because the engineering and maintenance schedules were not integrated.

It is also common to see departments forget prep, lockout/tag-out, permitting, handover and hand back, startup checks, quality assurance, etc. Smaller tasks like these are usually what delays a job and possibly the overall shutdown/turnaround schedule.

Turnaround Work Cutoff Date

A cutoff date is defined as the last day that any new work can be added to the shutdown – including projects, maintenance, installations, etc.

As the schedule is integrated, a cutoff date must be determined. The reason to have a cutoff date for work added is to manage scope creep or avoid any late work that has not been planned and scheduled. It is hard to be efficient if work has not been planned or scheduled because the person responsible and the time to do the work hasn’t been decided on, and parts or specific skills needed to do the work may not be available.

There should be an add-on policy in place that requires written approval by both the operations manager and the maintenance manager to add jobs after this deadline. The cutoff policy exists to manage the shutdown scope so that adding unplanned and unscheduled work late is avoided. The cutoff time should provide a reasonable time to plan and schedule so everyone is prepared when the job starts. Best practice is to have at least two months cutoff time for an annual shutdown or turnaround.

As mentioned, there are two more phases of shutdown turnaround management. Those are the Execution phase and the Critique phase, you can learn more about these two phases in our book “Shutdown Turnaround Optimization Process – A practical guide or by attending our training course either at your site or our HQ.

If you want to check the health of your shutdown and turnaround management process, we have a free assessment you can download.