Part of your work management after a plant shutdown is to do a team evaluation so you can improve your plant shutdown turnaround maintenance process.

A closeout review or critique meeting gathers all the information from the last event so you can prepare for the next event.

It is the ammunition your organization can use to either support the current Shutdown Turnaround Outage process as cost and safety effective or to challenge how the process is currently performed.

Unfortunately, many organizations either don’t do the review or have the meeting and do not use the information to improve the next shutdown turnaround cycle.

But that can change.

Here’s How To Improve Your Plant Shutdown Turnaround Maintenance Process

Capturing the Right Information

The effectiveness of the closeout review is directly related to the information captured during the execution of the shutdown/turnaround. During the execution you should be capturing information including:

- Was it on time?

- Was it on budget?

- Was all priority work completed?

- Was any work delayed or had a scope change?

- Were work delay codes entered into properly into the CMMS?

- Did the handover and hand back go as planned?

- What was the condition of the equipment?

- Did all resources work as planned? (Contractors, shifts, maintenance, operations)

- Were all infrastructure and logistics needs accomplished?

- Were all materials staged?

- Were Work order feedback forms logged?

- Was progress communicated daily?

- Were KPI’s met or adjusted?

- Did the overall plan perform as expected?

- What work is left for the next shutdown cycle?

- Was a lessons learned process flow followed?

Who’s Responsible for the Closeout Review?

Ultimately, the plant management team is responsible for ensuring that the closeout review is completed and effective. They are accountable for ensuring that all the Shutdown Group Stakeholders attend the closeout review.

Prior to the meeting, they should have an agenda with clear objectives and during the meeting maintain a constructive meeting (no finger pointing, everyone’s input is valuable).

Each stakeholder group (management, maintenance, engineering, stores/purchasing, contractors, operations) is responsible for reviewing their metrics and performance.

A good way to do this is to have each group complete self-evaluations. These evaluations are a good reflection of how each believed the shutdown was performed and should be compiled versus actual KPIs to help improve the next shutdown/cycle.

A best practice is to hold the meeting within a month of the complete shutdown.

This allows each group to review their metrics, compile results and reports and make a list of suggestions to be brought to the meeting to improve the next shutdown and to list work items to be added to the next shutdown or added to maintenance’s schedule if they work can be done as non-shutdown tasks.

This 6th and final Review in the Shutdown Turnaround Optimization Process could make your next shutdown more cost and time efficient.

For more information about how to improve your next closeout review contact us at [email protected]

IDCON’s Shutdown Turnaround Optimization Program includes 6 reviews of the Shutdown/Turnaround Process:

- Strategic Review

- Work Scope Review

- Plan Review

- Schedule Review

- Execution Review

- Closeout Review

These six reviews are designed to uncover and design the most effective shutdown process for your organization that focuses on how to bridge the gap between your current Shutdown Process and best practices.

By applying these 6 reviews, your organization can improve preparation, which impacts execution efficiency, cost, and usage of resources.

IDCON provides training and facilitation in all aspects of the Shutdown Turnaround Optimization Process.

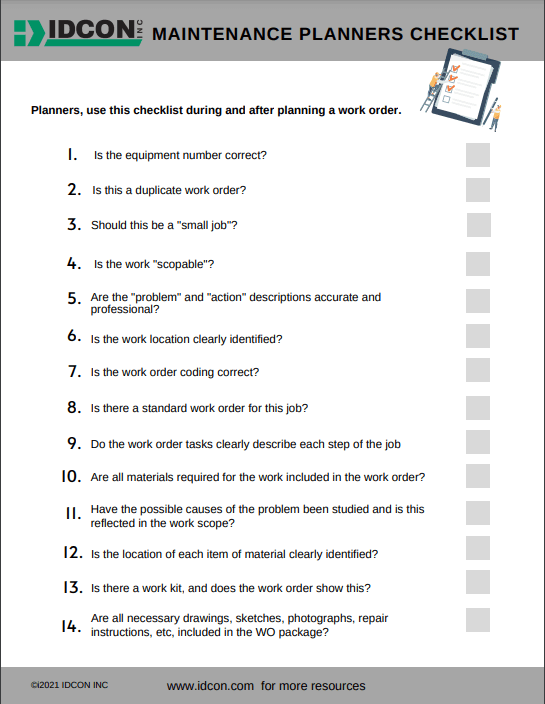

Download IDCON's Maintenance Planner Checklist (part 1)

This 28 point checklist will get you started on planning your own maintenance work.