If you don’t know by now, the maintenance planning and scheduling process is integral to reliability in industrial and facilities management. Over my 30 years in industry, I have seen a lot of mistakes in the managing of these interconnected processes. I’m detailing the most common planning and scheduling mistakes to avoid (of course, there are many more).

Need to understand the difference Planning and Scheduling? Read the comprehensive post: What’s The Difference Between Maintenance Planning and Scheduling?

Want to see the videos for this series, you can watch them on our YouTube channel.

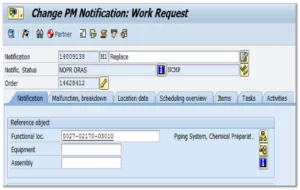

The first step an effective Planning and Scheduling process is to initiate (or identify) work. Everyone in operations and maintenance should initiate their own work requests directly in the Computerized Maintenance Management System (CMMS).

Where does maintenance work come from?

Most of the work requests should come from your PM system. At IDCON, we define Preventive Maintenance as all preventive tasks, condition monitoring, predictive tasks, analyses, continuous monitoring, and machine learning. In other words, PM is anything we do prevent and find failures.

Another way is when someone sees a problem that needs maintenance attention. (note – not every problem needs an immediate repair – see Prioritization further in this post)

Planning and Scheduling Mistakes to Avoid

There are 5 common planning and scheduling mistakes to avoid in the initiating (identifying) work process that we’ve encountered at client sites. As you go through this list, think about your plant, are these mistakes you are making?

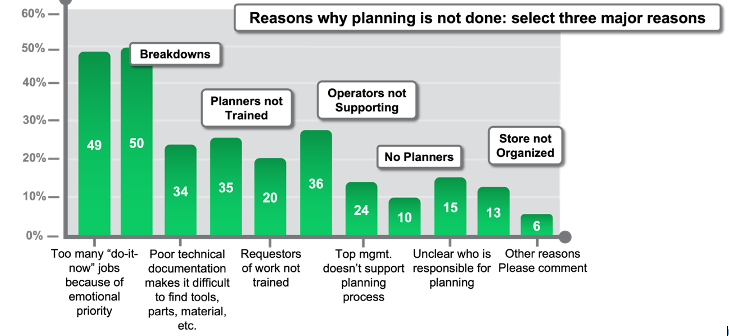

1. Operations does not support the Planning and Scheduling process

I have seen in some organizations where operations do not support the Planning and Scheduling process. They may not realize that they are responsible for certain tasks. This can be solved with better communication between operations and maintenance.

Ensure that operations understands the importance of Planning and Scheduling and that they are part of the front line of maintenance. Because the operations department operates the equipment, they need to inspect minor failures as they work, as well as performing preventive tasks. They are also responsible for keeping equipment clean.

Maintenance needs operations to report maintenance issues and create a work request so that maintenance has time to plan and schedule, including ordering parts and making sure the right crew members are assigned to the work order.

Do you need to get your operations and maintenance in sync? Our online course “Introduction to Maintenance Planning and Scheduling” is a great way to get everyone in your plant the same baseline understanding of the importance of planning and scheduling.

2. Operators and Maintenance Techs are not properly trained.

It is important that every organization has a Standard Operating Procedure for how to write work requests. This should be a simple, one-point lesson including refreshers on how to log in to the CMMS and which information to include in the work request.

All Operators and Maintenance Crafts should be trained on how work is requested. Ultimately, the best way to handle work requests is via the CMMS.

3. Operators and/or Maintenance Crafts do not have access to the CMMS.

Again, everyone in Operations and Maintenance should be able to write their own work requests and enter them in the CMMS. Therefore, supervisors and managers need to ensure that all operators and maintenance crafts have access to the CMMS.

Many times, leadership and/or administration will want to avoid having too many user licenses. But what happens when the supervisor doesn’t have time to help someone log in? What if they forget? At IDCON we believe that it is important for everyone to be able to write their own work request.

4. Finding failures early is not rewarded.

Another common problem we find is that the organization does not reward or recognize crewmembers for finding failures.

It is easy to focus on the person or crew that fixes the equipment once is already down instead of someone who finds a failure before it happens, because breakdowns require much more attention. Don’t just celebrate the repairs, celebrate the people who identify the problems.

5. The PM system task does not have the right content.

Your Preventive Maintenance system must have the correct content to drive generation of work requests. If there is not a good PM system in place, there will be no work to Plan and Schedule. Equipment problems and work that needs to be done is not being identified, so Planning and Schedule can’t be done.

The next step in the maintenance planning and scheduling process is the

Screening and Approval (or rejection) of work requests. This is step often missed.

Here are the top 4 planning and scheduling mistakes to avoid in the screening and approval of work requests.

1. Operations does not support the planning and scheduling process. SEE #1 in Initiating work!

2. Break-in work is not screened.

Failing to screen break-in work can cause interruptions.

If your organization hasn’t hired or properly trained an Operations-Maintenance Coordinator, the Operator will call Maintenance Techs directly if something comes up, interrupting scheduled work whether it is an emergency or break-in work or not. This, in turn, increases cost and lowers workforce efficiency.

3. There is no workflow describing the task with roles and responsibilities.

The Planner in an organization should always be focused on future jobs (at least four weeks ahead) to allow for sufficient lead time, ordering of materials, hiring contractors and scheduling services, etc.

If there is no workflow for Planning and Scheduling describing the task with roles and responsibilities, the Planner will not be able to plan and might become involved with break-in work, which should not happen. At IDCON, we coach that Planners are an essential role and must be allowed to plan

Take our Why Planners don’t Plan survey to give your input!

4. Work requests are not screened for quality and duplication.

Work requests are often not screened for quality and duplication and when they are, the procedure is not always followed correctly, which leads to confusion.

If a duplicate work order is found, feedback needs to be sent to the requester of the work when it’s cancelled. Otherwise, they won’t understand why the work was cancelled and they may enter another duplicate work request.

Other times, the screeners deem a request of poor quality and cancel the request without checking the scope with the original work requestor.

Again, this leaves the work requestor confused as to why the work was cancelled. This takes us back to why it is important to train the team properly on how to write a work request. Quality work requests are less likely to be cancelled.

Maintenance Work Prioritization

Part of any effective planning and scheduling process is prioritizing the work. Again, we’ve seen a lot of mistakes surrounding work prioritization. Here are the top 4 planning and scheduling mistakes to avoid while prioritizing maintenance work:

1. There is no formal work priority system in place.

To keep a formal work priority system in place, the crew must be trained properly and understand how the priorities are used so they understand why prioritization is important.

If there isn’t a good work priority system in place, there is no way to sort the work order list or the backlog by priority. It is important to be able to sort the priorities so there is a guide for which work orders to plan and schedule first.

When you don’t have priorities, everything is a priority. Need a simple priority guideline? Download one for free

2. There is no priority system in the CMMS.

Part of a good priority system includes the Computerized Maintenance Management System. Priorities need to be recorded with jobs in the CMMS, and the organization needs to ensure that the CMMS system uses priorities instead of just work order types such as PMs, repairs, etc.

3. It is difficult to assess risk because the focus is on determining the probability of a breakdown.

It is easy to be distracted by trying to figure out when a breakdown will occur, but it is a better use of time to monitor the condition of the equipment to determine its status. Trust your experience and the tools you have (which are only getting better). Learn about what defines a failure vs. a breakdown here.

4. Operations and Maintenance are not working as a team.

The Operations Maintenance Partnership requires the operations and maintenance departments to work together to minimize total losses. It requires each department to communicate and clarify roles and responsibilities in the partnership. It is not a good use of time to question each other’s actions instead of communicating and cooperating. Crew safety, impact on customers, stakeholder and investor interests, the bottom line, and total operating cost are all affected by the partnership between Maintenance and Operations.

Planning Mistakes to Avoid

One of the biggest planning and scheduling mistakes to avoid in the planning process is when planners are not used for just planning work. So how can you avoid this mistake?

- Clarify the role and responsibility of the planner

- Protect your planner (if possible) from filling in for supervisors and purchasing

Learn more about the Maintenance Planner’s roles and responsibilities and the skills they need.

Backlog

Biggest mistakes: The Backlog is often misunderstood and not managed properly If you don’t manage your backlog of work it can lead to duplicate work requests and work not being completed in a timely manner. This can lead to mistrust in maintenance on the operations side. Which in turn can lead to prioritizing requests higher than warranted.

What is the purpose of Backlog Management in Planning and Scheduling?

- To track, quantify, and manage the work in the backlog so that it is not forgotten and is completed per agreed priorities and schedules.

- To manage the workload based on the resources at hand and to adjust resources by trade, area, department, and work type to the workload.

- To make strategic and tactical decisions regarding contractor use.

- To analyze the content of the backlog and take necessary actions to address any work process, quality, competency, or other problems identified.

The backlog should be managed based on the equipment needs, not against the maintenance budget. When mandatory work doesn’t get done, reliability will go down over time.

If the backlog is too large, the maintenance manager will need to decide whether it will be enough to move trades between areas, use overtime, bring in contractors, or even hire new trades.

Although the planner typically manages the backlog process (including setting up frequent meetings to discuss trend), the maintenance manager should be the one to make decisions for the organization based on the backlog trend.

How is the backlog target set? A good rule of thumb for process industry is to have a target between 4 to 6 weeks.

If the target is fewer than 4 weeks, the backlog may not have enough work to keep the crew busy. If the target is more than 6 weeks, the crew probably wouldn’t be able to complete tasks on time or before a breakdown occurs.

Want to learn how to calculate the backlog? Here’s a 2-minute video that explains how to do it!

I hope that this post of these common maintenance planning and scheduling mistakes to avoid will help you! If you find that your workload is out of control, contact us and we’ll help you devise a plan to improve your work management system.