Infrared (IR) thermography has become an essential tool in many Predictive Maintenance (PdM) Programs.

In spite of becoming more user-friendly and affordable, there is a tendency to set the IR camera on the shelf once the electrical switchgear hotspot survey has been completed.

Many Preventive Maintenance programs include inspection steps and tasks that would be greatly enhanced in effectiveness by applying IR technology.

For example, in a high-speed packaging environment using an IR camera to image hard to reach bearings and gearboxes and couplings may allow failures early in the Failure Development Period to be detected well before the failure has progressed to breakdown.

As a reminder, there are two basic steps to get a useful image: FoRD “Focus, Range and Distance”.

The information one may extrapolate from a thermo-gram is crucial to a proper diagnosis and must be as precise as possible.

Understand and adjust for emissivity and reflectivity. By carefully evaluating the area of inspection, these two factors may have a direct effect on proper interpretation of a thermo-gram.

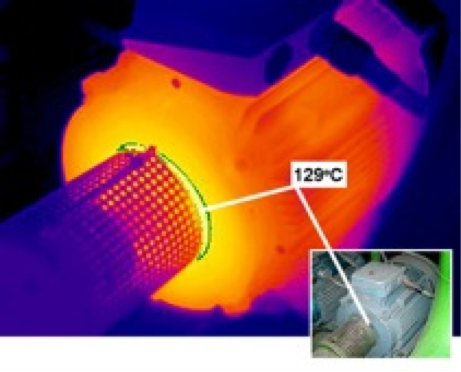

Pictured below are useful thermographs that may be used to identify a failure developing into a breakdown.

Many plants have guarding that has not been modified to allow access with an Infrared Temperature gun or an accelerometer to allow vibration readings to be taken.

Infrared Thermography may be a viable alternative inspection method to monitor component condition.

A Preventive Maintenance survey route may be enhanced to include Infrared Thermography along with other inspection techniques based on component failure modes to detect failures early.

Do your Maintenance Technicians and Planners need to know the fundamentals of developing essential care and condition monitoring care and inspections?

Attend IDCON’s PM Development and Essential Care and Inspection Techniques Training