Over the past 10 years, the North American diesel fuel market has slowly moved from High Sulphur fuel to Low Sulphur fuel (< 500ppm) and eventually to Ultra Low Sulphur (ULSD) fuel (<15ppm). With these changes, new problems have arisen.

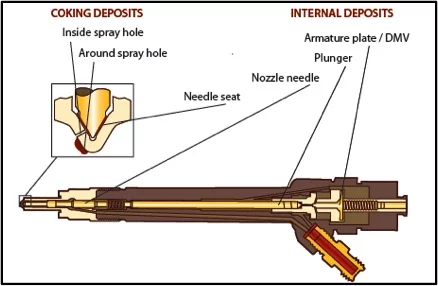

One of the largest problems has been the increased failure rate of fuel injectors. And the most surprising problem is not an electro-mechanical failure but rather it is a seizure between the needle and the seat.

With a lot of problem solving and testing have come some very surprising results. To make a very long story short, the seizures are caused by the formation of salt and it is the salt that is causing the “sticking injectors”. More specifically, these are Carboxylic acid salts that are being formed by the combination of Sodium and Corrosion Inhibitors found in modern day ULSD.

The Sodium can come from a variety of sources. Some of these are refinery salt dryers, storage tank water bottoms, seawater (ship ballast), etc. The Corrosion Inhibitors, which is primarily dodecenyl succinic acid DDC Acid) and hexadecenyl succinic acid (HDS Acid), comes from pipeline drag reducer, refinery corrosion inhibitors, refinery neutralizing agents, additive packages and other aftermarket products.

These two components combine to form these problematic salts that have very poor solubility in ULSD and are only partially affected by filtration. With the high fuel pressures found in the modern day common rail diesel fuel systems, and the close internal tolerances of the fuel injectors, these salts find a home at the junction of the needle and seat.

Has your injector life been dramatically reduced? Are you also seeing increased fuel filter plugging? Are you seeing a very dark substance on your fuel filter media? If the answer to these questions is “Yes” then salts have attacked.

The only real solution for the end-user is to stabilize their fuel; which is primarily accomplished by “treating” the fuel with an aftermarket additive. And be forewarned, not all aftermarket additives are created equal. Work with a reputable company that is aware of this problem and has done the research on dealing with this problem. Act quickly and decisively and you should see a very quick reduction in fuel injector consumption.