What is Reliability Consulting?

Reliability consulting is a structured approach aimed at enhancing the overall dependability and performance of a company’s operations, equipment, and processes. The focus is to minimize operational disruptions, reduce downtime, and ensure the longevity of equipment. As a reliability and maintenance consulting firm, IDCON specializes in this field, and our goal is to help you increase plant reliability while maintaining safety and cost-efficiency.

What's the Reliability Consulting Process?

The reliability consulting process begins with a comprehensive evaluation or assessment of your current maintenance and reliability practices. This step is essential to understand the challenges you face, such as recurring breakdowns, high maintenance costs, or ineffective work management processes.

Based on this evaluation, we develop a tailored action plan with you. This plan will address your specific needs and ensures that your team will not be overwhelmed with competing initiative.

Implementing Your Maintenance and Reliability Action Plan

A critical aspect of the reliability consulting process is to support the plant as they implement the changes. While your plant is absolutely capable of implementing your action plan, experience has shown that having expert support can speed up the process.

IDCON support includes working side-by-side with your team. We provide practical training, mentoring, and coaching. This hands-on approach ensures that your team not only learns but also applies the learning needed for sustainable improvements.

Our consultants are experienced professionals who understand the complexities of plant operations, having worked in similar environments themselves. This practical experience allows us to identify hidden inefficiencies, streamline processes, and develop solutions that can be integrated seamlessly into your current operations.

What Maintenance and Reliability Consulting Services do Organizations Need?

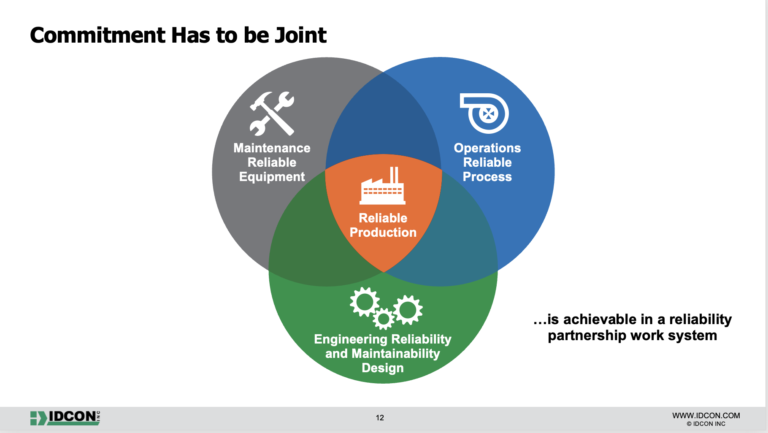

IDCON believes the key to improved maintenance and reliability is the efficient execution of preventive maintenance, essential care and condition monitoring (ECCM), work management (planning and scheduling), materials management, root cause problem elimination, and shutdown and turnaround optimization. But reliability production is not limited to the maintenance organization, it is the joint commitment between maintenance, operations, and engineering.

What Industries Benefit from Reliability Consulting?

Reliability consulting can be applied across various industries, from manufacturing and processing plants to power generation facilities.

For industries where continuous operation is critical, such as power plants, oil and gas, and heavy manufacturing, reliability consulting is essential to avoid costly shutdowns and ensure a safer working environment. In these sectors, reliability improvements directly impact not only operational efficiency but also regulatory compliance and safety standards. Industries like food processing, pharmaceuticals, and electronics manufacturing also benefit significantly from improved reliability, as it ensures product quality and reduces waste, meeting both customer demands and industry-specific standards.

Outcomes of Improved Reliability

Improved reliability translates directly into higher equipment uptime, meaning fewer unplanned stoppages and higher productivity. With properly maintained equipment and well-planned preventive and corrective measures, your team can focus on optimizing production rather than constantly reacting to emergencies.

Cost savings are a major benefit when organizations focus on reliability and maintenance best practices. When equipment operates reliably, there are fewer repairs and replacements required, leading to reduced maintenance expenses. Moreover, reliability enhances safety by minimizing the risks associated with unplanned and unscheduled maintenance, thereby contributing to a safer work environment for your staff. Lastly, a reliable plant is a more efficient plant, allowing you to meet production targets consistently and deliver high-quality products or services to your customers.

We Understand the Pressures of an Unreliable Plant

If you are seeking to improve reliability and achieve long-term operational success, IDCON is here to support you. Our expertise in reliability and maintenance consulting, paired with hands-on coaching and practical solutions, ensures that we can guide you towards your goals. Contact us today to discuss how we can help optimize your plant’s performance and make reliability the standard in your organization.

"*" indicates required fields