The Covid-19 pandemic is still creating casualties around the globe and many companies’ finances are shaken to their core. If you manage maintenance, you are probably feeling constantly under pressure to lower costs.

Sometimes you may even be ordered to lower maintenance costs with X % and that within a certain time frame. This is probably the near reality for many. Maybe you are already in that pinch? If so, how do you handle it? Lowering the maintenance cost, of course, but how? What steps do you take?

I have some thoughts and arguments that may help you discuss the situation with your peers.

First of all, I think you should ask for a meeting with the person who has decided to lower maintenance costs.

I know, it may not be possible, but you should at least try. And if there is any time in history you should be persistent, it is NOW.

Decisions regarding lowered maintenance costs are rarely logical or based on reasonable data. Most of the time your factory has been compared with a similar factory and some ”genius” (an accountant or top consultant) has just looked at the total maintenance cost this year, perhaps a couple of years, WITHOUT considering or including:

- the age of your factory

- what maintenance work processes you have in place

- the size of your maintenance debt

- your relationship with the union

- what you include in maintenance cost (varies wildly between companies)

- what major jobs you did (or didn’t do) last year, etc.

Comparing maintenance costs between plants will always give you a distorted picture.

Your plant may be the second-best in the world, but when it’s compared to the one plant better than yours, you may be asked to cut maintenance costs. You need to question why the cost should be cut and perhaps more importantly, how! Does the company need to ask if a maintenance cost reduction really will improve the company’s result (profit)? It may make sense that if maintenance cost goes down, profit will increase. Many have been mistaken in this assumption.

As an example, let’s assume you have a high maintenance debt, meaning that your backlog of repair work is really big (could be identified or unidentified backlog). You may have a big backlog because of years of neglect and/or previous cost cutting. Your maintenance cost probably is big compared to others, because you are trying to catch up on repairs. So, an accountant would say that the cost must come down. I would agree, the question is how?

If you have a lot of valid repairs, they can’t be avoided, I don’t care of you are a maintenance manager, plant manager, VP, CEO, or the Queen of England, you can’t make it go away by any others means than repairing the equipment. They have to be repaired! This is important to understand, unfortunately, most people don’t. You could repair equipment now for the cost of 1 or wait till you have a breakdown and pay 3 to 9 times more. That’s the choice, there are few other choices. You could use your resources more efficiently and/or reduce new repairs with better Preventive Maintenance (PM), but such a change takes time, often years.

So, the question is not really IF you should try to reduce the maintenance cost, you should. The question is how and when, and that is a VERY important question.

There are only a few approaches available. One alternative is to lower the maintenance budget immediately and hope that maintenance somehow becomes more efficient and we get all the backlog work done. Unfortunately, this is a very common and very bad solution. Repair work for equipment that already is identified has to be done regardless of how much someone wants to reduce your lower the maintenance cost. And all the while, you also cannot become more efficient in just a few days.

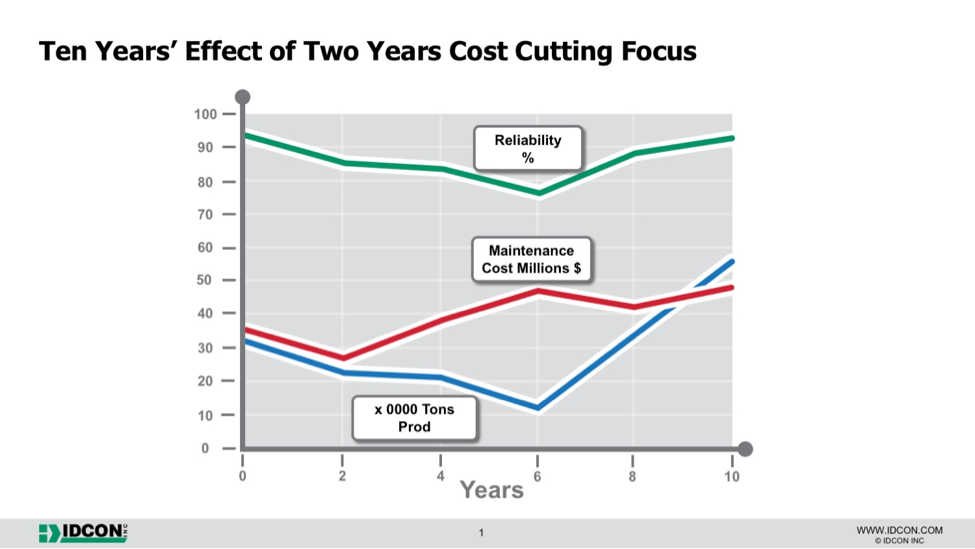

What typically happens if you reduce the maintenance budget quickly is that repairs are delayed, which causes more breakdowns and more downtime, which obviously also leads to higher costs. The image below shows the effect of cost-cutting in a European paper mill.

A quick maintenance reduction causes a delayed effect, and it isn’t a good one, at least not for you.

The first 6 or 9 months will look good, and then…the results will plummet. If this is how the organization wants to solve the current situation, make sure you find another job within 9 months. Maybe you should become a top consultant or accountant ;-).

Improving sustainable maintenance practices takes time.

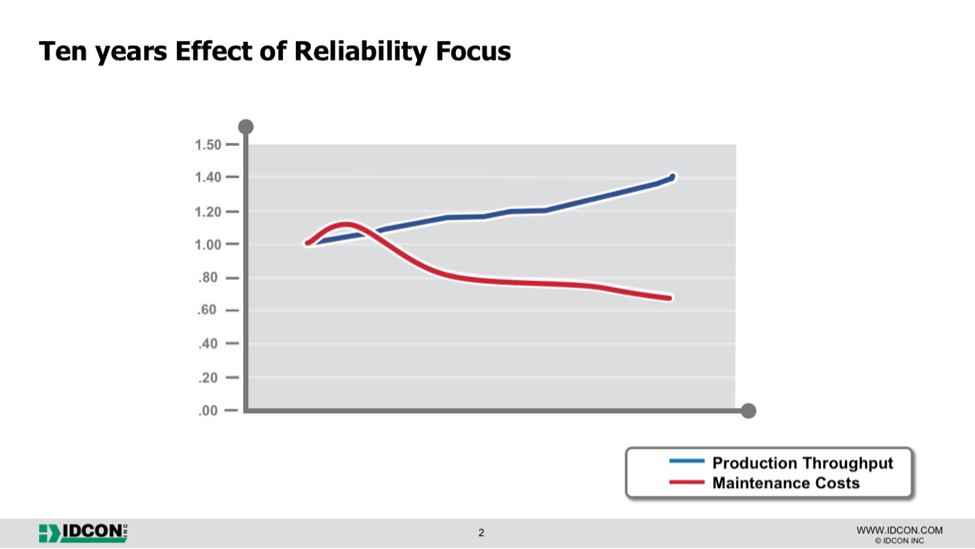

And that is because it’s 90% about changing human behavior. To be tough, bark out orders and threaten, doesn’t help. No, there is only one remedy—time and leadership. Taking the time to improve work processes through people is typically a great investment because once work is rolling smoothly, reliability will go up and because of that, cost WILL go down. IDCON has collected many studies from a vast variety of plants around the world over the years.

Most plants can improve operating procedures, lubrication routines, and precision installation. Most of us also need to improve “the chain” inspect-plan-schedule-execute.

The image below shows the effect of a focus on reliability at an operation in New Zealand.

A note. There are ways to improve maintenance quickly, but work systems must improve to sustain those improvements, and that change takes time.

My advice in short:

- Discuss whether the cost really should be reduced in a short time period.

- Usually, the answer to bullet 1 is no. So, focus on improving your work processes through strong leadership with your people. Your reliability will go up and cost will go down as a consequence. This option is much better than cutting cost in panic and hoping reliability will be OK.

You will find many more articles and videos on our website – please visit www.idcon.com/free-resources

Please check out our discussion page on linked in: https://www.linkedin.com/groups/3300952/

Subscribe to our YouTube channel: https://www.youtube.com/channel/UCRsdOmCZX4GSZMpqAdFhw3A/