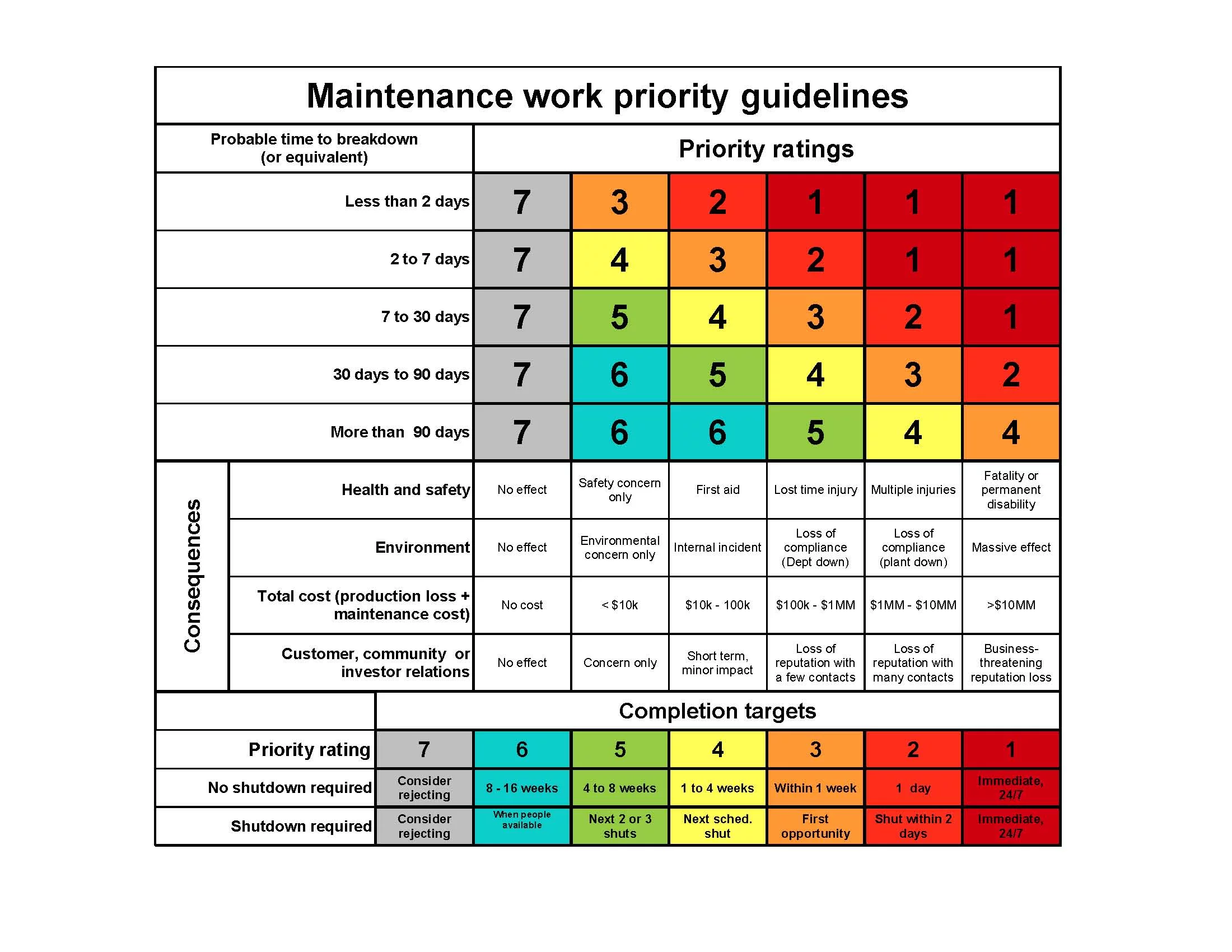

One of the exercises in IDCON’s Work Management Planning and Scheduling Training is to assign the right priority for jobs.

Setting priorities for work requests is an important aspect of the Work Management process. When you have priorities defined and FOLLOWED you know that break-in and unplanned work is going to be minimized. Let’s see how well you understand using a priority guidelines. Read the three scenarios and use the priority matrix to assign a priority rating to each situation and send your answers to [email protected]

Setting Priorities – 3 Scenarios

- A) A Vibration Analyst reports increased vibration in the input shaft bearing in the reducer that drives a critical raw material conveyor. It is being monitored frequently, and it appears to be a minor defect in the outer race.

The opinion of the analyst is that it will last 2 to 3 months before it gets serious. From your experience, you know that a shutdown is required to change this reducer and takes about 4 hours. Unscheduled downtime costs $5,000 per hour and the cost of changing and repairing the reducer will be about $1,500.

- B) A couple of leaks have developed in the roof over the finishing line. An inspection by a roofing expert showed that the wooden roof deck has some areas of rot. Some of these areas are above equipment, which could be damaged by water. The roofing expert believes that if the roof deck is not repaired several more leaks will develop within a year. The estimated cost of the repairs is $100,000 and the cost of possible equipment damage and production loss from water leaks is in the range of $10,000 to $50,000 per event.

- C) In a monthly review meeting, the Plant Manager tells his staff that the operation is in financial difficulties, and that new capital is urgently needed. A potential new investor will be visiting the plant in 3 weeks and it is important that the place looks well maintained. The main entrance sign to the plant is damaged and should be replaced before this visit. He asks the Maintenance Manager to look after this.

Do you need your organization to understand why using the right Priority is important? Get Basic Training in Work Management.