It’s important for maintenance leaders to have a good understanding of their organizations’ front lines in order to influence improvements. The maintenance personnel that make up the front line are, in most cases, independent, which can be good but can also be a pitfall.

It’s great that the staff manages daily operations, but how can leaders set goals and influence quality of the work if they are not involved in or in-the-know of the activities on the floor?

When it comes to change management or improvement, it’s as important to have clear goals, as it is to offer practical support and implementation.

Many leaders I meet feel that it’s enough to tell their employees what needs to be done. I often hear that they have held a meeting and informed everyone about what needs to be done, and then assume that the workers are going to follow the instructions and plans that were communicated in the meeting.

The problem is that humans don’t quite work that way. If we did, we could throw a 10-minute meeting on TV explaining that everyone should eat less and jog more and voilà, all obesity would disappear.

We could also add another five minutes to tell people about smoking, drugs and alcohol consumption and we’d rid the world of those problems, too. The human mind doesn’t always do what’s logical or best.

We tend to do what we like best in the moment, wherever we are, consciously or sub-consciously.

Information meetings are very important, but we cannot expect changes and improvements magically happen just by having a meeting.

There are many ways to create and implement changes, proven by the miles of books written on ”Change Management.”

IDCON works these types of problems out through practical coaching. Recently we implemented root cause problem elimination in an organization.

They wanted to improve how operations and maintenance personnel systematically work with problem elimination.

Not only did we run an interactive workshop, but also we set goals beforehand and then worked together in solving the problems. The method is similar for planning, scheduling, preventative maintenance and materials management.

Specify expectations before the workshop

It’s common to forget what it is we want to accomplish. Goals can be hard to formulate in a clear way. In this case, the first goal the group worked with was to ”Improve root cause analysis” (RCA).

That goal was pretty vague since it didn’t have a timeline, and therefore cannot be measured, and, it was hard to define what ”improvement” meant.

So, together we worked up how we could define improvement in this case with some simple key points:

| Documentation | Actions | Follow-up |

| A process description for problem solving | An automatic trigger to start root cause analysis | 5 solved problems are looked over by teacher/ IDCON every six months per area |

| Course material we can use for internal training | All areas do root cause analysis of unplanned stops, longer than 4 hours | Area supervisor follows up on priority meetings |

| A tool to document cause-and-effect diagrams | All foremen and hourly employees within operations and management are trained in root cause analysis | |

| Etc. | Etc. | Etc. |

Adapt the training for each company

We used IDCON’s standard training with the company’s own examples, workflows and computer systems. Every course participant was asked to contribute to the workshop with something they defined as a problem.

The participants were also asked to save broken parts from equipment, data from processes, and so on. We had eight reality-based examples to work with at the start of the workshop, three of which were process-related and five machinery problems.

Educate and Interact

In our experience, it’s not just classroom training that creates change. There are more steps needed in a successful change process, after specific goals have been set.

- Theory: Creating an overview of expectations

- Show: Creating an understanding for how things are to be done

- Hands-on: Field exercises with a supervisor/manager

- Follow-up: Top management has to follow up & follow through

We tailored a five-day training with 40 percent classroom time and 60 percent hands-on work.

The course was held in a room adjacent to the factory floor and consisted of three main parts:

- Theory and discussion about problem solving through work processes, critical thinking and cause-and-effect documentation.

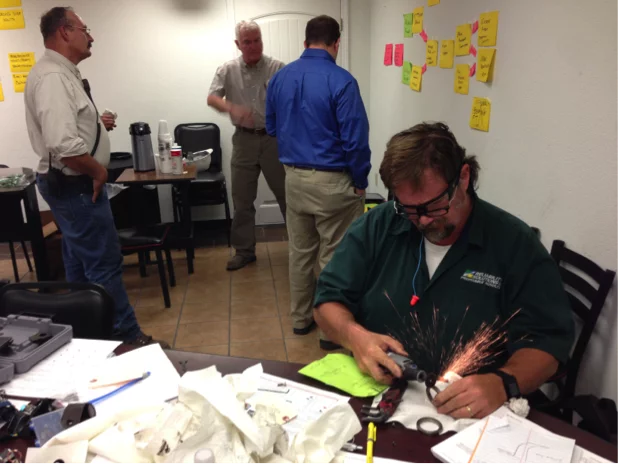

- Technical investigation of broken parts (ball bearings and transmissions), lubrication problems and repair.

- Exercises in solving these in-house problems with the help of IDCON.

Together we solved six of the organization-specific problems, four machine breakdowns and two that were process-related.

IDCON’s consultant shown analyzing a broken bearing. In the background we are documenting our logic in a cause-and-effect diagram.

Hands-on exercises

We gave the participants homework. They are to solve two problems over the coming two months, and then they will present their findings for company management and IDCON.

We will be available on site for two weeks offering support to this particular factory.

Follow-up

The production managers in all different areas of the company are now well grounded in the process and responsible for following up on the results. IDCON’s role will be phased out, but first we will leave the bosses with a structure to follow.

We will work to both set up automatic triggers and to integrate the root cause analysis in the daily scheduling meetings.

Summary

Changes in people’s work habits and methods are hard to implement just through instructions.

I believe that we have to educate, involve, allow worker input and offer hands-on interaction for perspective.

Let those who are working on the floor or in the field practice hands-on, and let management follow up on wherever the problems occur or changes are needed.

The ultimate idea is to create an internal focus group, or use an external resource like a consultant to get changes started.